Application US5020307A

1989-08-08

Guenter E. Gutsche

1989-08-08

Guenter E. Gutsche

An improved method and apparatus for water harvesting wherein a separator grating is lowered into the water to hold trash below the harvestable berries that are then caused by their buoyancy to rise through the immersed separator. The berries thus separated from the debris are gathered in various ways, such as the conventional loading via a conveyor, removing the berries by lifting the separator grating after the apertures of the separator have been reduced, or using a second grating with smaller openings. The method can be carried out in a reciprocating cycle or using a continuous rotating movement of the separator that might be part of a band scoop, mechanically powered scoop, or rolling harvesting apparatus. Provisions are also provided to simultaneously remove the debris separated from the berries from the flooding water. The method and apparatus might also be used in cleaning the harvest in a flooded tank on the dike.

1. Field of the Invention

The present invention relates to water harvesting apparatus and more particularly to methods and devices to separate cranberries from debris floating in the water during the harvesting.

Cranberries that are destined for processing into juice and sauce are normally mechanically beaten off their vines. This is done after the bog has been flooded to raise the vine by the buoyancy of the berries. The beating process also dislodges vines and other debris or trash as well as the leaves off the plants that then remain in suspension in the water in the interval between the beating operation and the gathering of the berries. At the point of loading the cranberries onto the conveyor there are typically encountered two distinct types of trash or floating debris.

1. Field of the Invention

The present invention relates to water harvesting apparatus and more particularly to methods and devices to separate cranberries from debris floating in the water during the harvesting.

Cranberries that are destined for processing into juice and sauce are normally mechanically beaten off their vines. This is done after the bog has been flooded to raise the vine by the buoyancy of the berries. The beating process also dislodges vines and other debris or trash as well as the leaves off the plants that then remain in suspension in the water in the interval between the beating operation and the gathering of the berries. At the point of loading the cranberries onto the conveyor there are typically encountered two distinct types of trash or floating debris.

First the many small leaves typically about 1/2" by 1/4" in size that are routinely washed off the berries without much difficulty prior to loading into the moving vehicles. Second, various lengths of torn vine, weeds, grass, pine needles and other windborne particles. Because this type of trash intertwines with more than one berry, it has proven difficult to separate once it has been gathered with the cranberries. Growers regularly experience financial losses because of rejection of part of their shipments due to the presence of this trash. Further, a considerable part of the potential harvest is lost in the matting, entrapping berries that can not be economically freed once the floatsam has been moved out of the water. The prior art shows several attempts to separate harvestable fruit from rejects by their specific weight or dimension. One such example is the U.S. Pat. No. 2,976,992 to Bloch.

In this device the greater buoyancy of closed and sound nuts is used to separate them from less buoyant and open rejects. A number of processes and devices have been contemplated to classify minerals and ores at processing plants using a combination of gratings and flotation processes. As only one typical example might be cited the U.S. Pat. No. 1,461,067 issued to Moser, which uses grating of various fineness to classify grades of gravel passing through them.

In this device the greater buoyancy of closed and sound nuts is used to separate them from less buoyant and open rejects. A number of processes and devices have been contemplated to classify minerals and ores at processing plants using a combination of gratings and flotation processes. As only one typical example might be cited the U.S. Pat. No. 1,461,067 issued to Moser, which uses grating of various fineness to classify grades of gravel passing through them.

SUMMARY OF THE INVENTION

The present invention is differenciated from the prior art separation processes that attempt to separate rejected matter after the gathering of the harvest by doing the separating while the berries and debris are still mixed in the water of the flooded bog or separator tank. It also differs from the prior art separators in a further aspect, in that the selected material or crop is moved through the separator grating upward into the collector by buoyancy. In one embodiment of the invention the invented method uses one synergistic motion of a submersible separator or grating that both depresses the larger trash into the water floating the berries and allows the buoyant berries to rise above the separator that then can be selectively restricted to serve also as lifting means to load the berries. In another embodiment the separator is in the periphery of a barrel shaped harvesting apparatus and the action of rolling the barrel or truncated cone through the water synergistically depresses the rejected debris, admits the cranberries into the harvester and lifts the fruit out of the water with the option to gather trash from the outside of the grating for disposal. In these many aspects the present invention is distinct and an improvement over the devices of the prior art.

It is accordingly the objective of the invention to provide a method that uses the abundance of water to allow the separation of large trash from cranberries prior to loading the crop.

The present invention is differenciated from the prior art separation processes that attempt to separate rejected matter after the gathering of the harvest by doing the separating while the berries and debris are still mixed in the water of the flooded bog or separator tank. It also differs from the prior art separators in a further aspect, in that the selected material or crop is moved through the separator grating upward into the collector by buoyancy. In one embodiment of the invention the invented method uses one synergistic motion of a submersible separator or grating that both depresses the larger trash into the water floating the berries and allows the buoyant berries to rise above the separator that then can be selectively restricted to serve also as lifting means to load the berries. In another embodiment the separator is in the periphery of a barrel shaped harvesting apparatus and the action of rolling the barrel or truncated cone through the water synergistically depresses the rejected debris, admits the cranberries into the harvester and lifts the fruit out of the water with the option to gather trash from the outside of the grating for disposal. In these many aspects the present invention is distinct and an improvement over the devices of the prior art.

It is accordingly the objective of the invention to provide a method that uses the abundance of water to allow the separation of large trash from cranberries prior to loading the crop.

Another object of the invention is to increase the portion of the berries grown to be delivered to the consumer.

A further object of the invention is to increase the revenue of the grower as well as the efficiency of the processing of water harvested cranberries.

Another object of the invention is to provide a variety of harvesting apparatus that increase both the efficiency and the quality of the harvest operation.

The objects of the invention are accomplished in the following embodiments, methods and steps.

In one aspect of the invention the method of separating floating trash from the cranberries is accomplished by lowering a submersible grating with apertures greater than the selected fruit into the water and then to gather the berries that have been floated through the grating or separator.

In another aspect of the invention the method is carried out by using a separator with variable or closing apertures and changing the aperture to a size smaller than the acceptable fruit and lifting the berries out of the water by lifting the thus constricted grating.

A further object of the invention is to increase the revenue of the grower as well as the efficiency of the processing of water harvested cranberries.

Another object of the invention is to provide a variety of harvesting apparatus that increase both the efficiency and the quality of the harvest operation.

The objects of the invention are accomplished in the following embodiments, methods and steps.

In one aspect of the invention the method of separating floating trash from the cranberries is accomplished by lowering a submersible grating with apertures greater than the selected fruit into the water and then to gather the berries that have been floated through the grating or separator.

In another aspect of the invention the method is carried out by using a separator with variable or closing apertures and changing the aperture to a size smaller than the acceptable fruit and lifting the berries out of the water by lifting the thus constricted grating.

The present invention is illustrated by way of example in the following drawings wherein:

FIG. 1 is a sectioned view of a deployed separator in a cranberry bog;

FIG. 2 is a sectioned view of an adjustable separator;

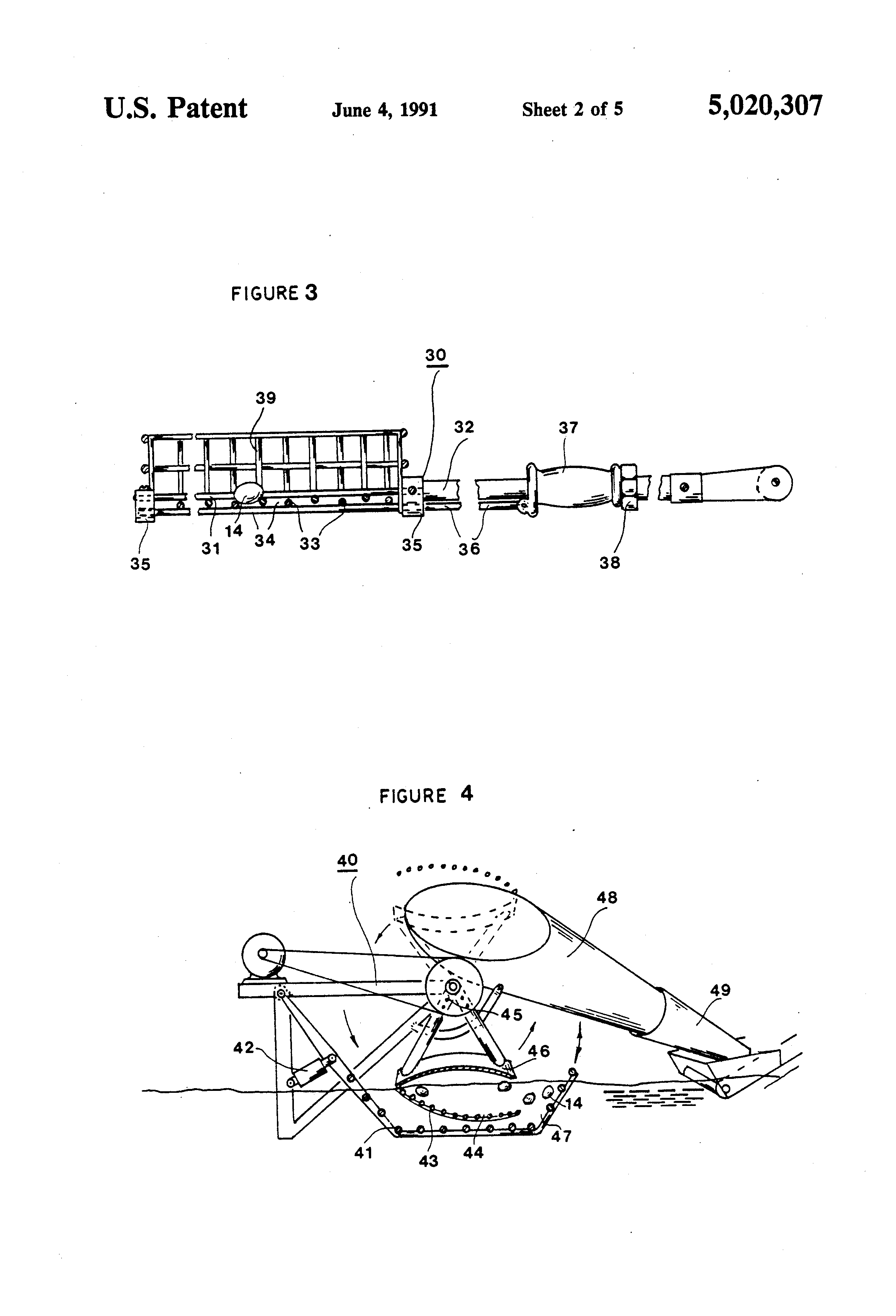

FIG. 3 is a sectioned view of a manual scoop;

FIG. 4 is a sectioned view of a powered scoop;

FIG. 5 is a sectioned view of a powered scoop;

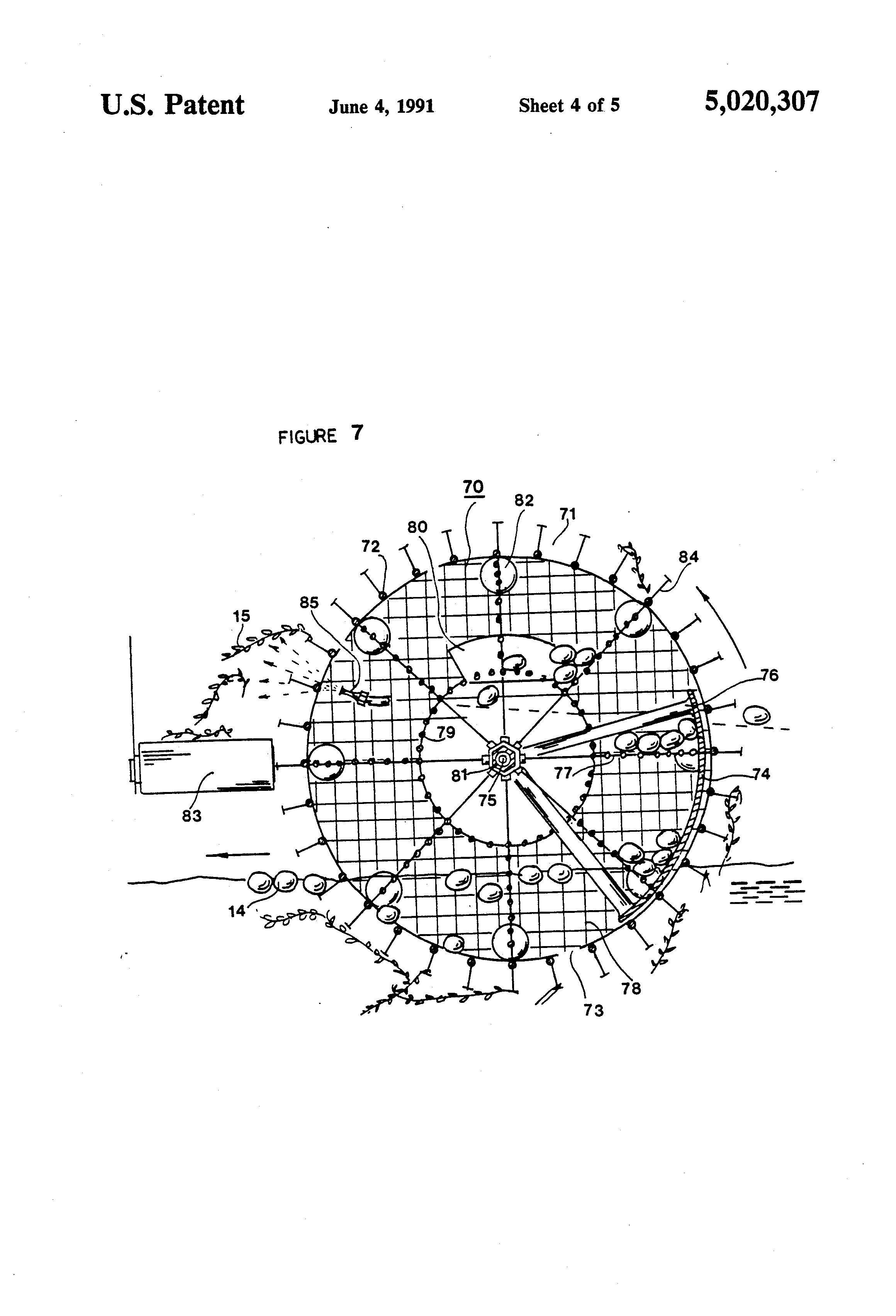

FIG. 6 is a sectioned view of a cranberry harvesting apparatus;

FIG. 7 is a sectioned view of a cranberry harvesting apparatus and

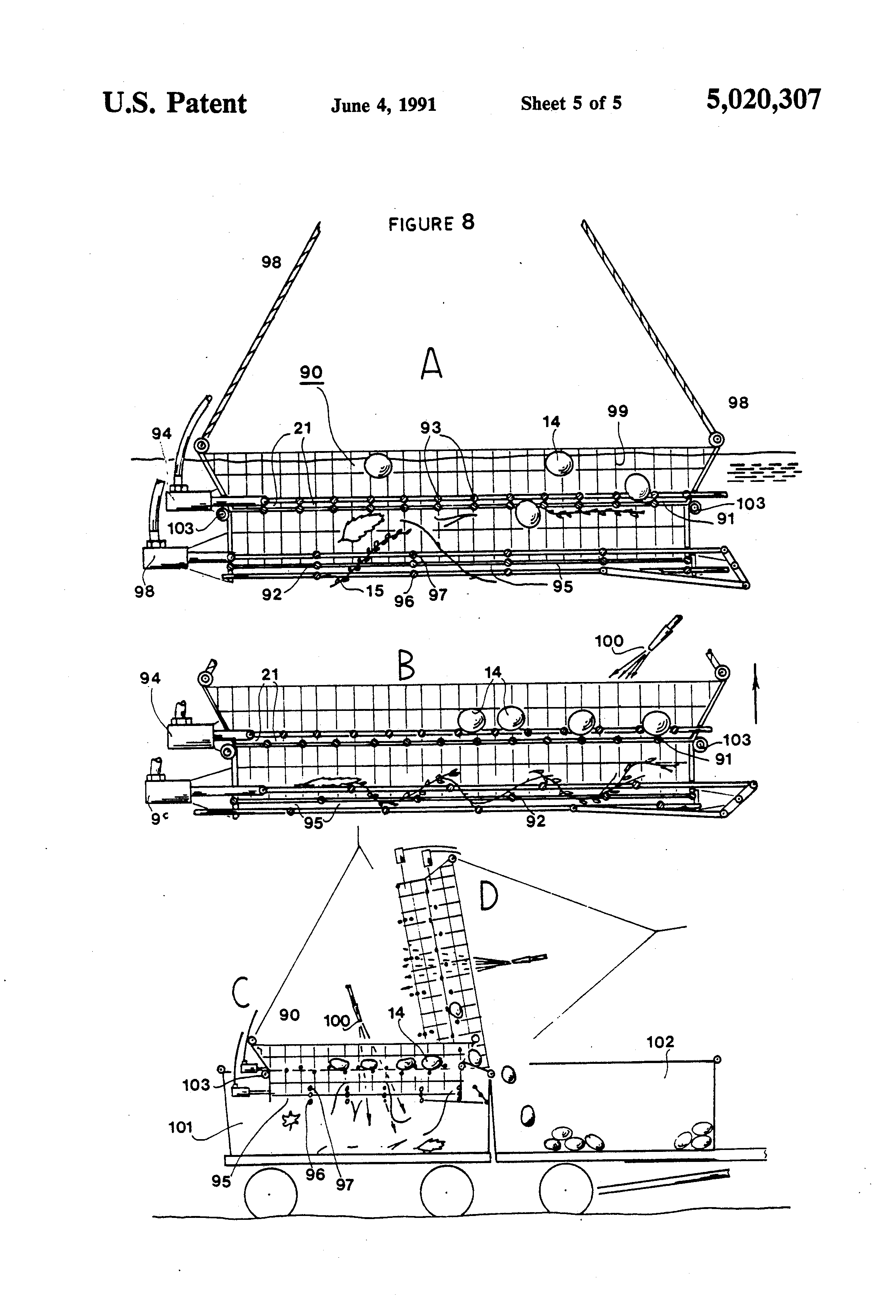

FIG. 8 is a sectioned view of a harvesting apparatus in four positions during the use of the invented method.

FIG. 1 is a sectioned view of a deployed separator in a cranberry bog;

FIG. 2 is a sectioned view of an adjustable separator;

FIG. 3 is a sectioned view of a manual scoop;

FIG. 4 is a sectioned view of a powered scoop;

FIG. 5 is a sectioned view of a powered scoop;

FIG. 6 is a sectioned view of a cranberry harvesting apparatus;

FIG. 7 is a sectioned view of a cranberry harvesting apparatus and

FIG. 8 is a sectioned view of a harvesting apparatus in four positions during the use of the invented method.

Cranberry Bog Harvest:

https://youtu.be/F1m7tCAA8Zk?t=94

https://youtu.be/F1m7tCAA8Zk?t=94