Studio

Spring 2019

Instructor: George L. Legendre

TA: Benjamin Hait

Selected for Platform 12

Presented at the IWBC Conference 2019

View on GSD website︎︎︎

Spring 2019

Instructor: George L. Legendre

TA: Benjamin Hait

Selected for Platform 12

Presented at the IWBC Conference 2019

View on GSD website︎︎︎

The interest of this project lies in a fluidity between living and packaging.

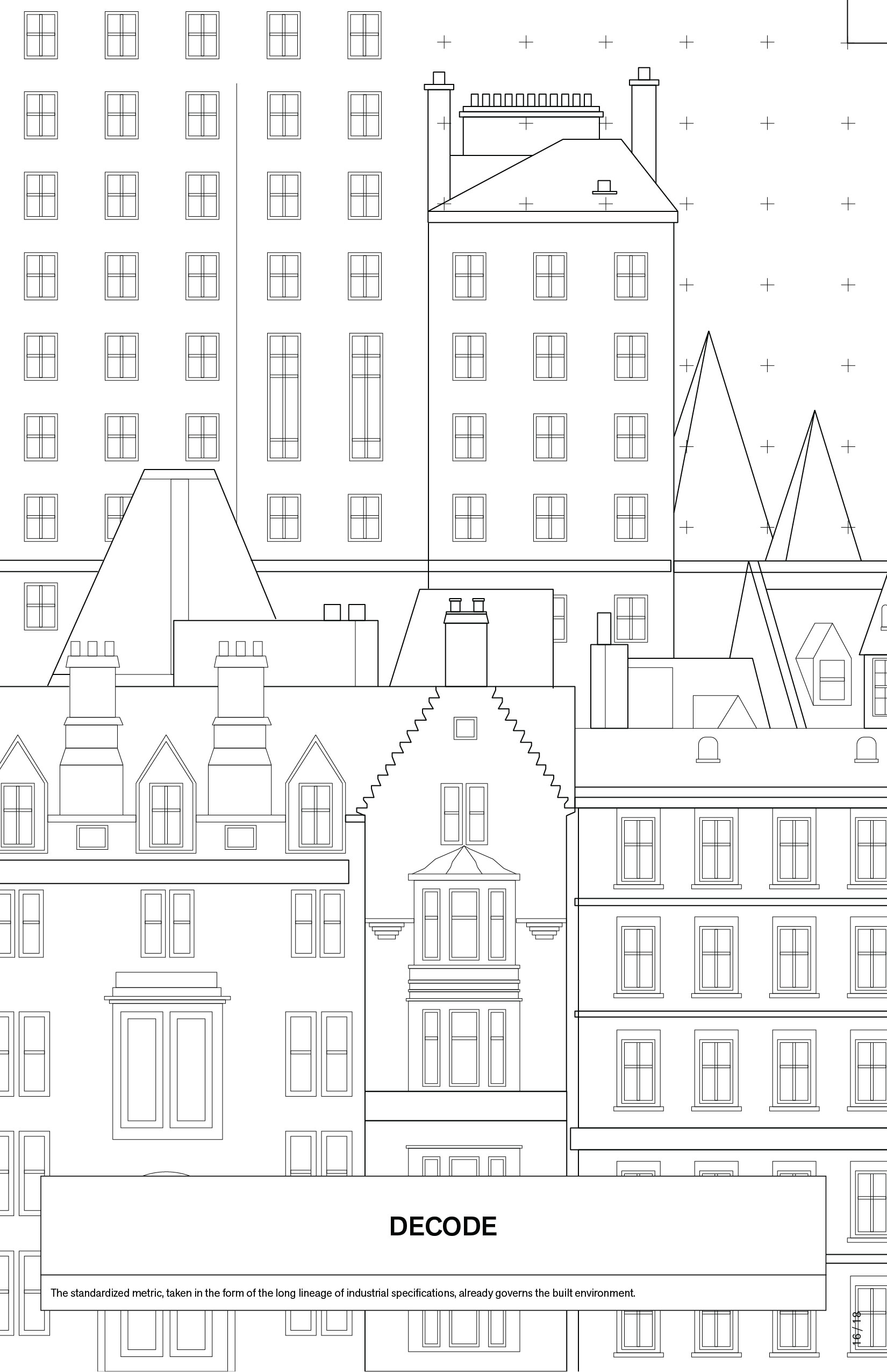

The most notable commercially packaged houses are perhaps catalogue homes produced by companies like Sears Roebuck that were popular around the 1920s. All materials for those houses would be packaged into a train container and delivered to the recipient, then built by contractors hired locally by the client.

The most notable commercially packaged houses are perhaps catalogue homes produced by companies like Sears Roebuck that were popular around the 1920s. All materials for those houses would be packaged into a train container and delivered to the recipient, then built by contractors hired locally by the client.

The first wave of mail-order homes died down during the great depression. Some kit house companies continued after World War II, but most homebuyers flocked to the new, inexpensive suburban cookie-cutter houses.

The latest attempt that resembles a catalogue house were Lowe’s Katrina Cottages, with walls designed to withstand 140 mile-per-hour winds, intended to provide temporary housing for residents who lost their homes to Hurricane Katrina. The product was unsuccessful and has since been discontinued because it was feared they would lower property values in neighborhoods.

The latest attempt that resembles a catalogue house were Lowe’s Katrina Cottages, with walls designed to withstand 140 mile-per-hour winds, intended to provide temporary housing for residents who lost their homes to Hurricane Katrina. The product was unsuccessful and has since been discontinued because it was feared they would lower property values in neighborhoods.

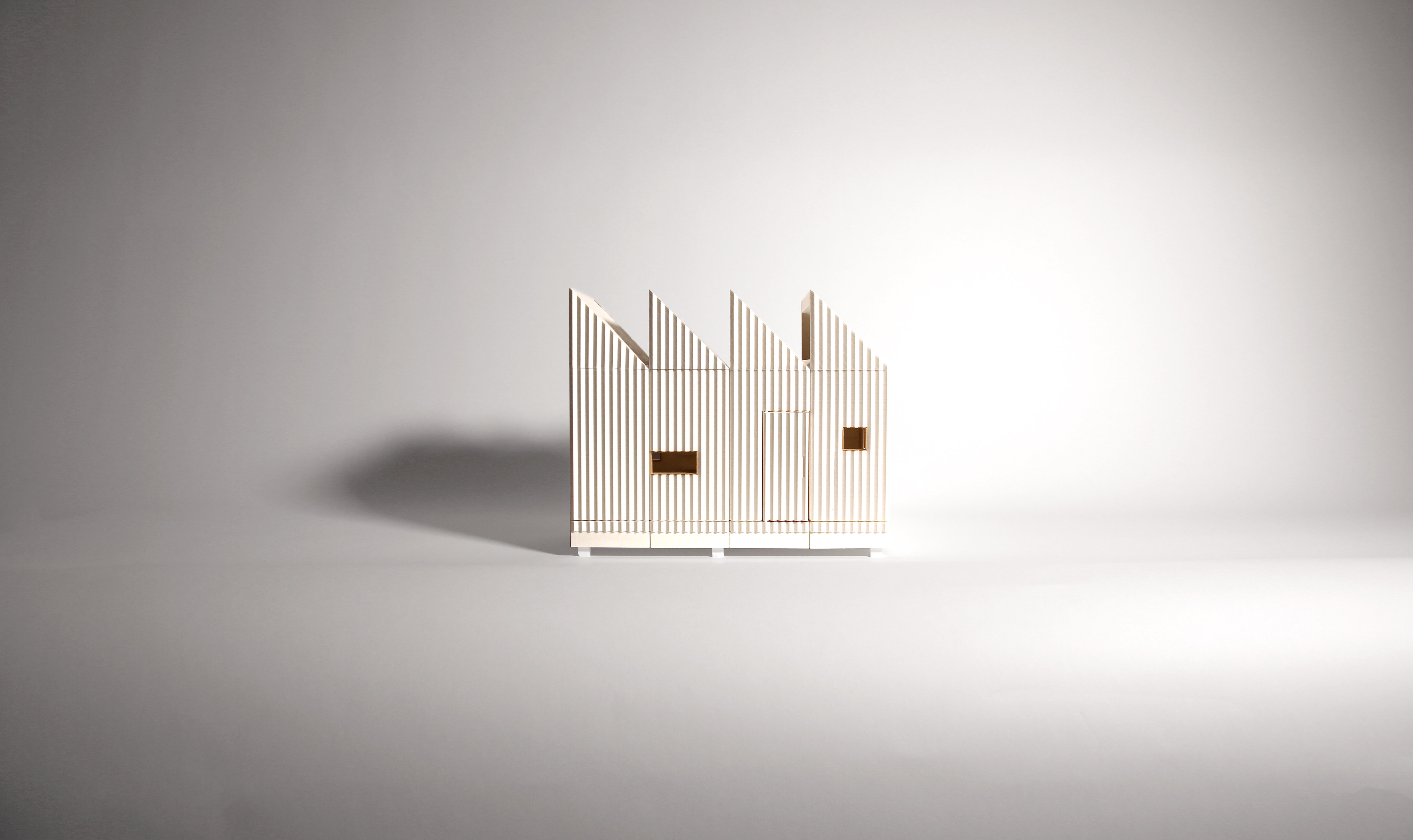

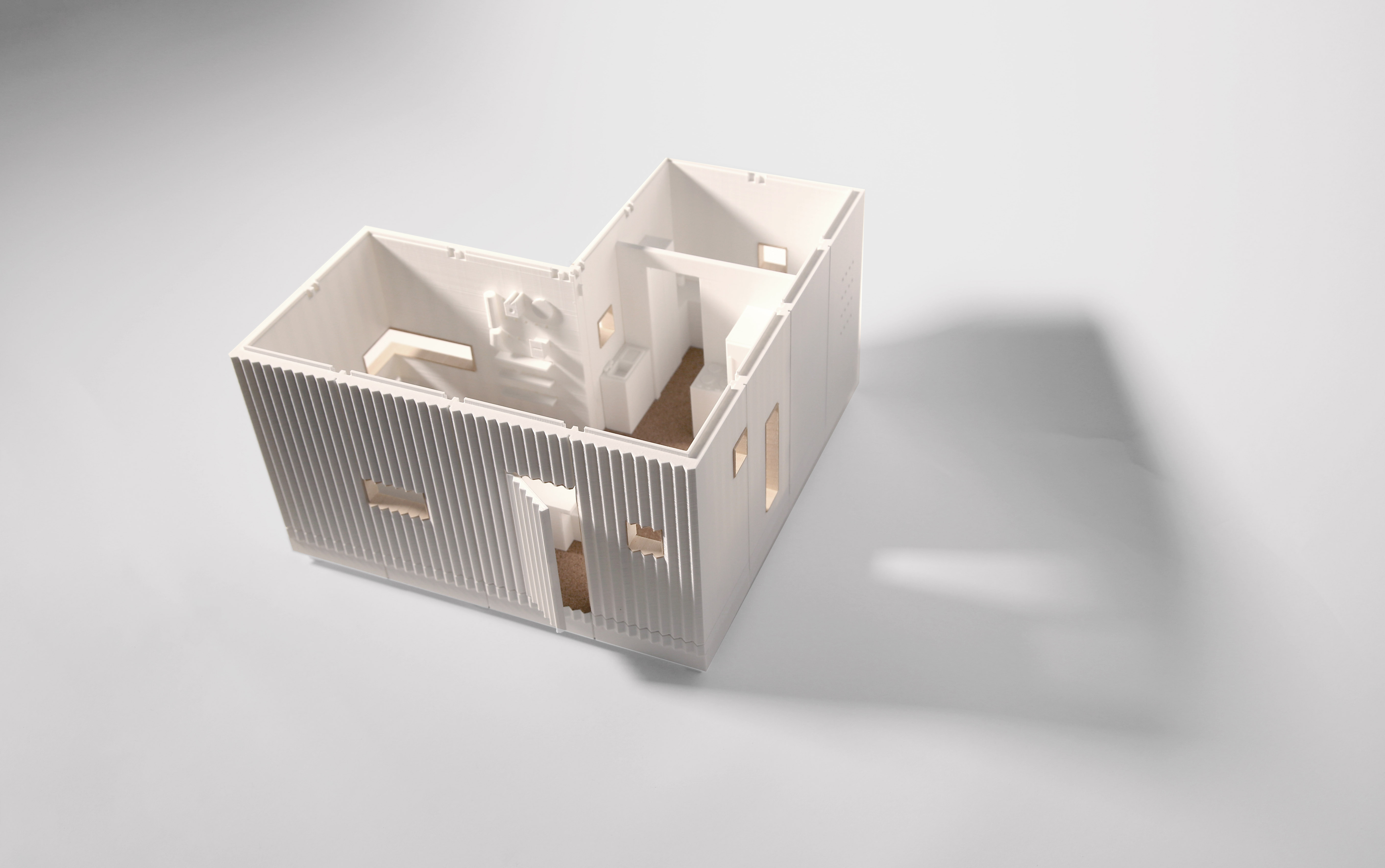

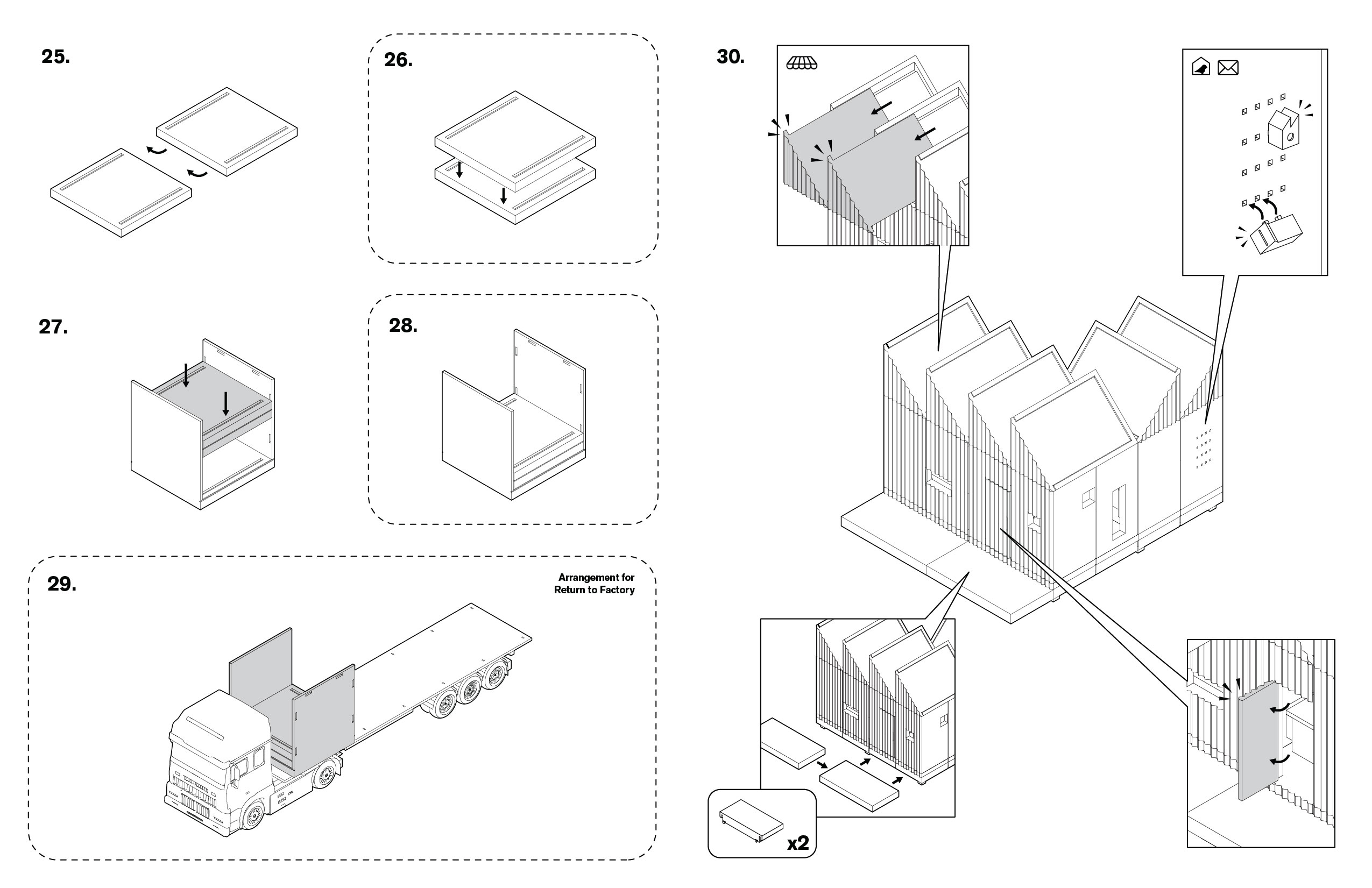

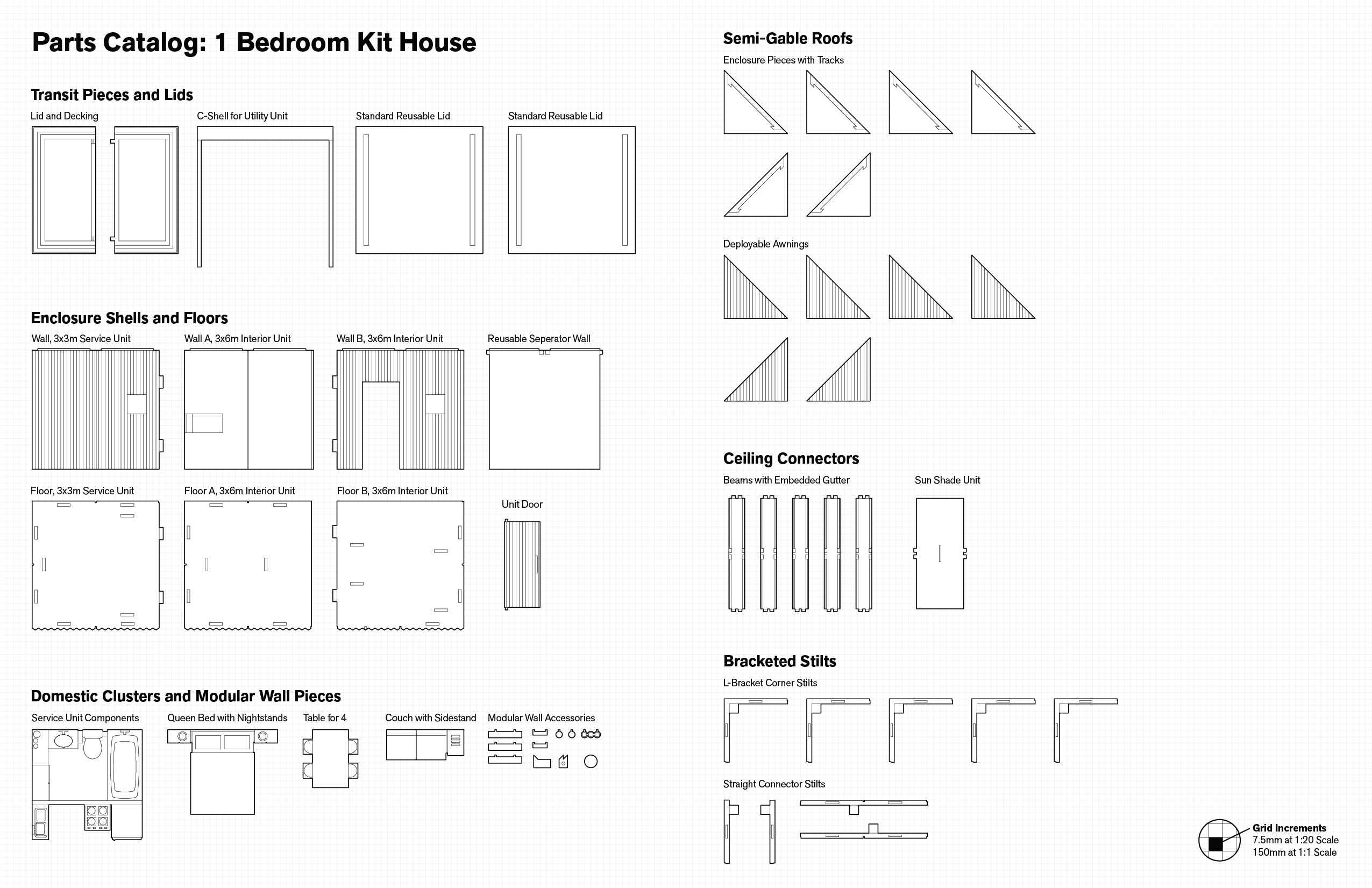

1-Bedroom Kit House, 1:20 scale

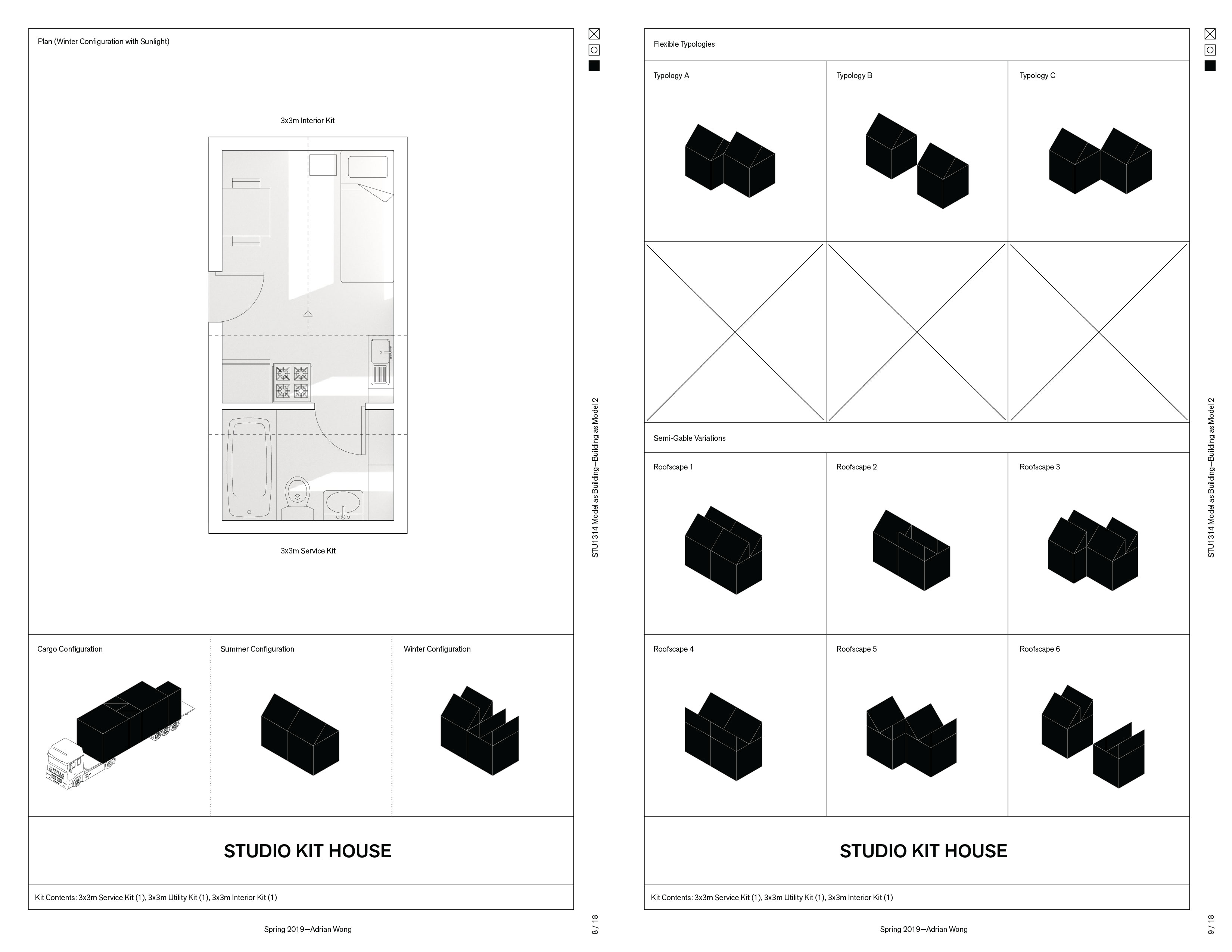

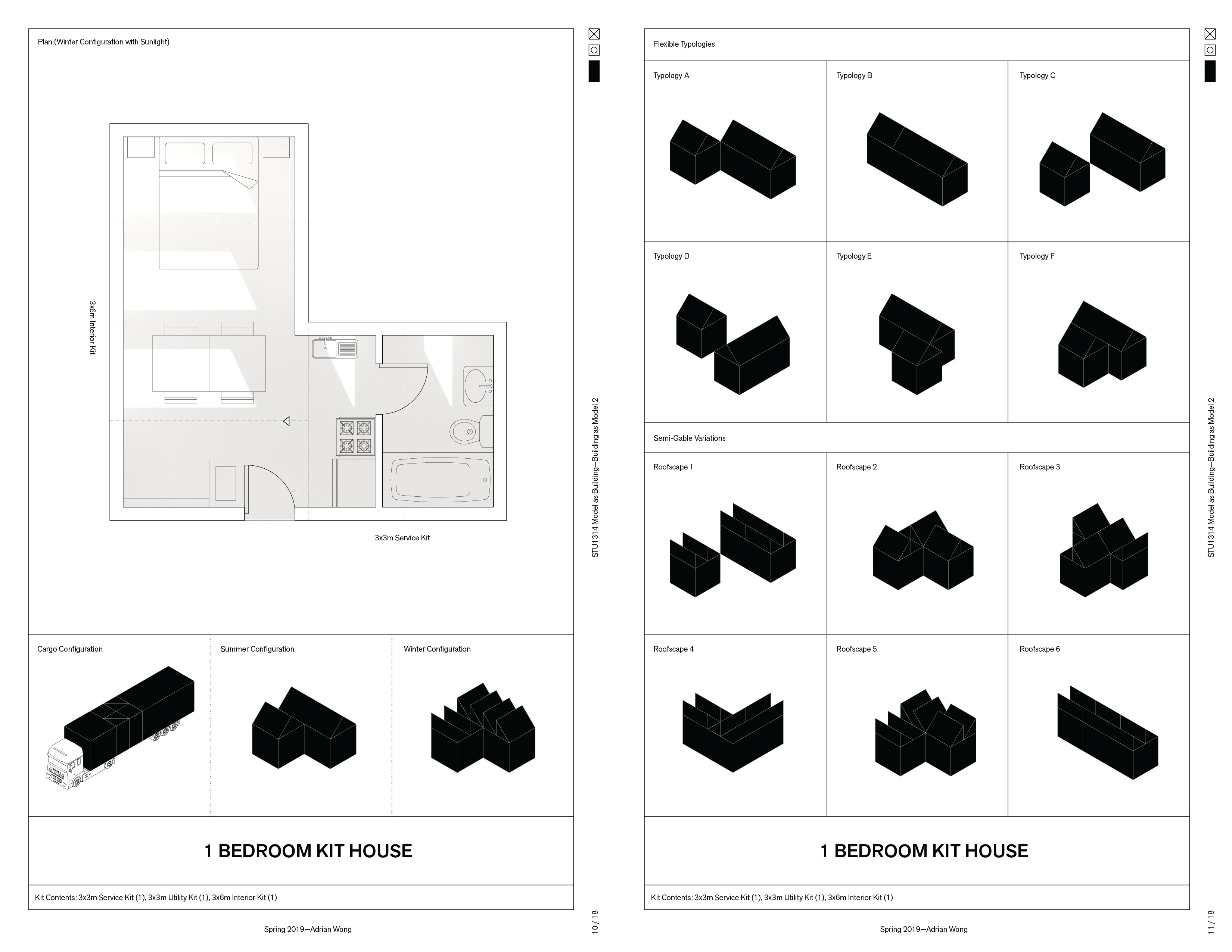

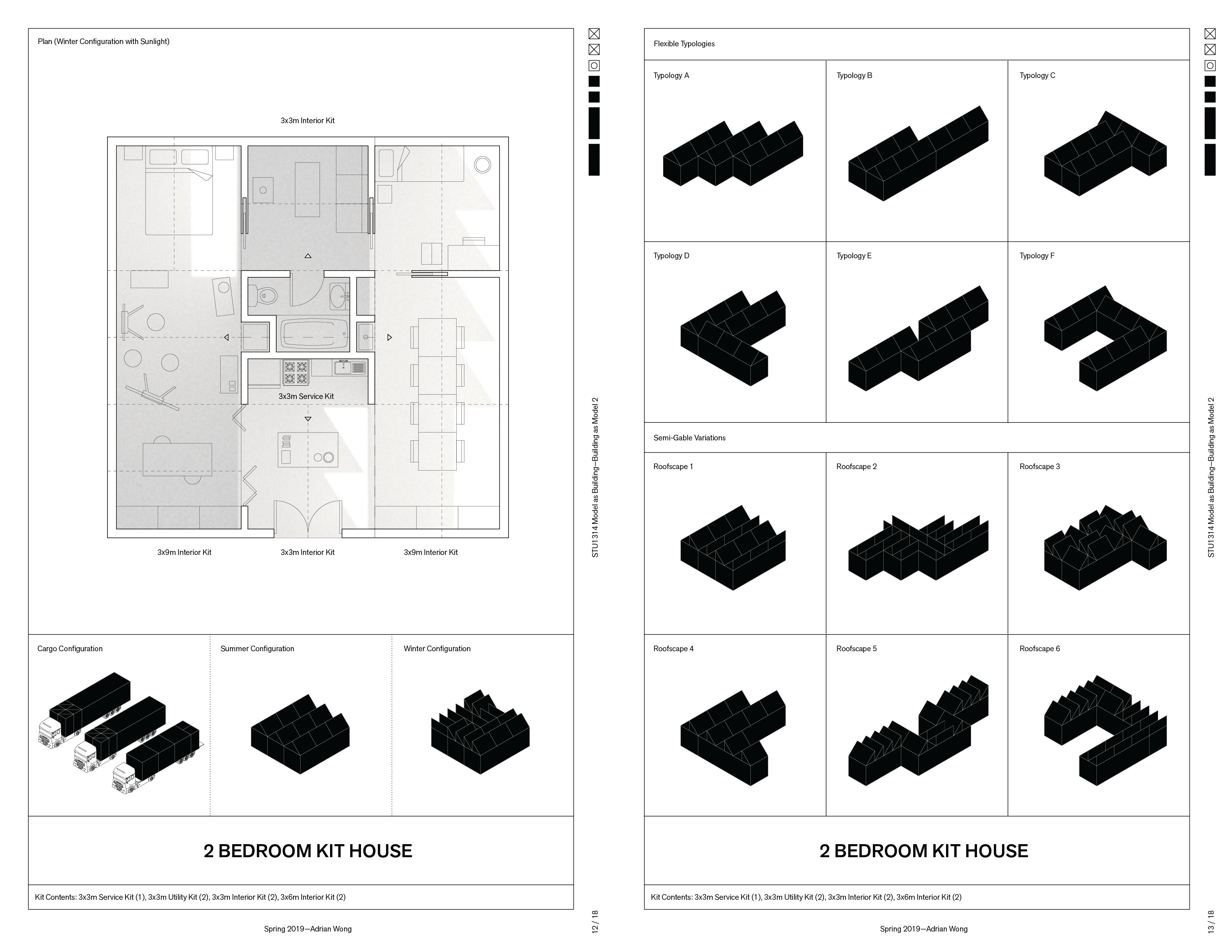

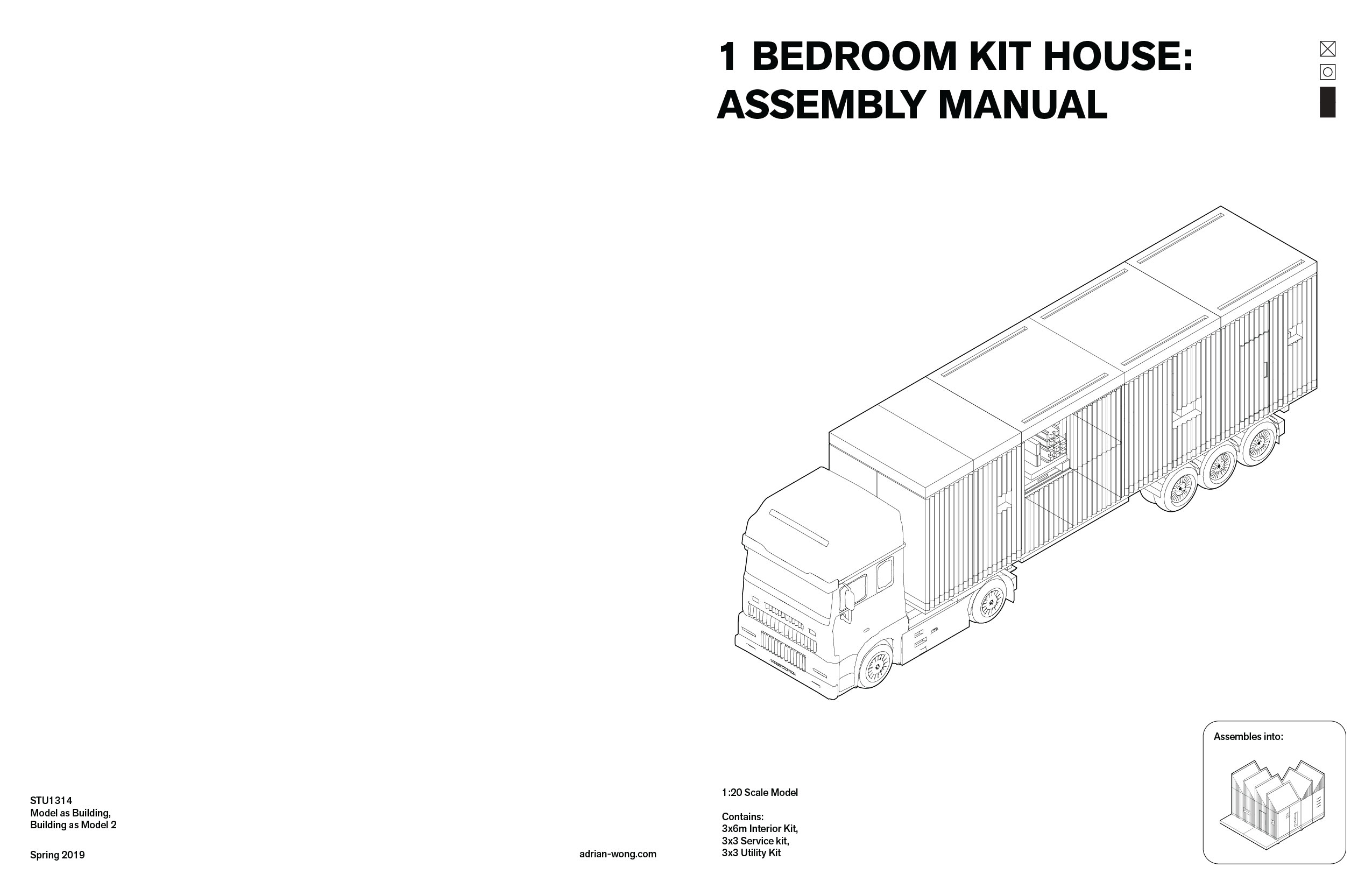

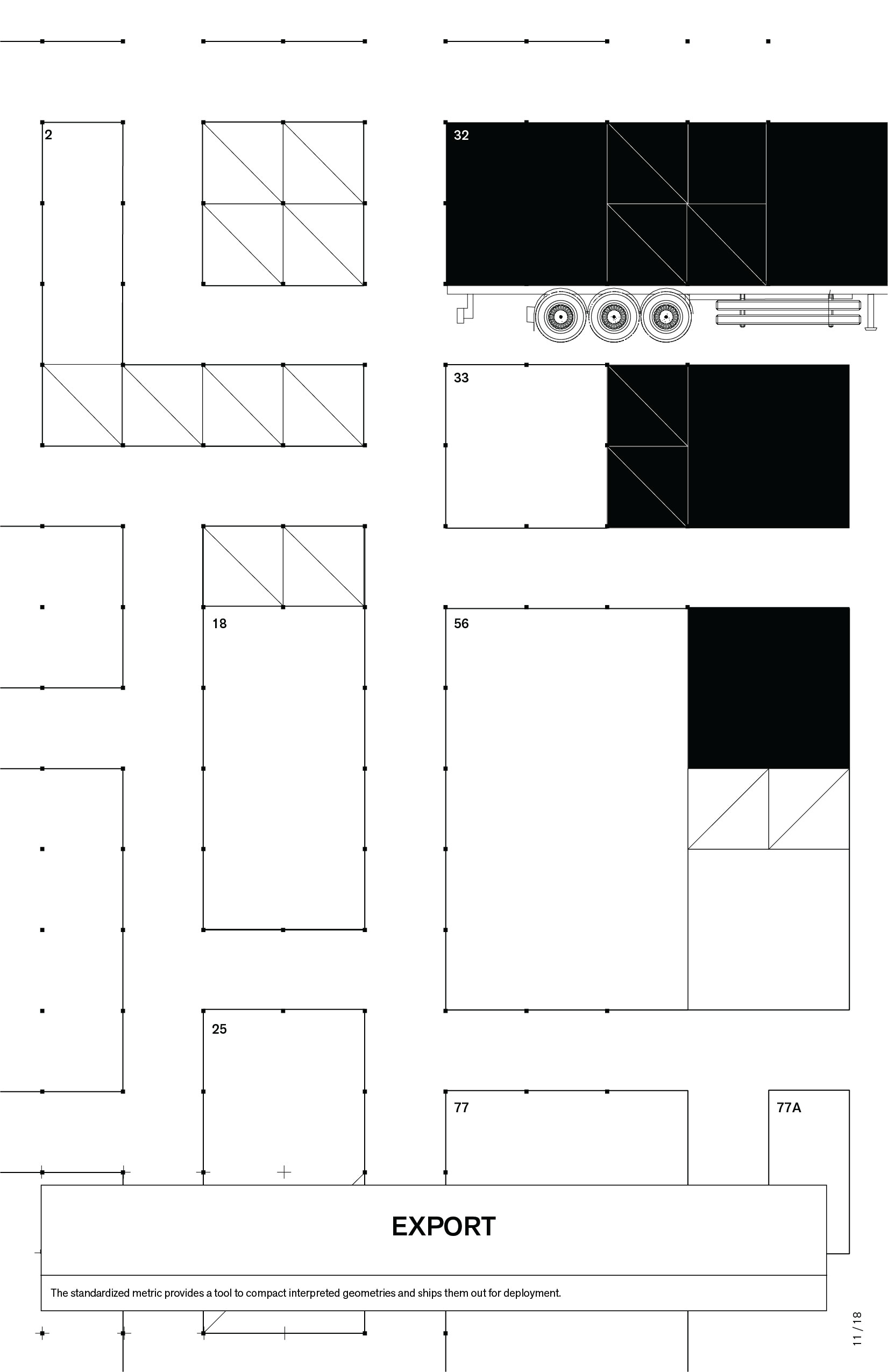

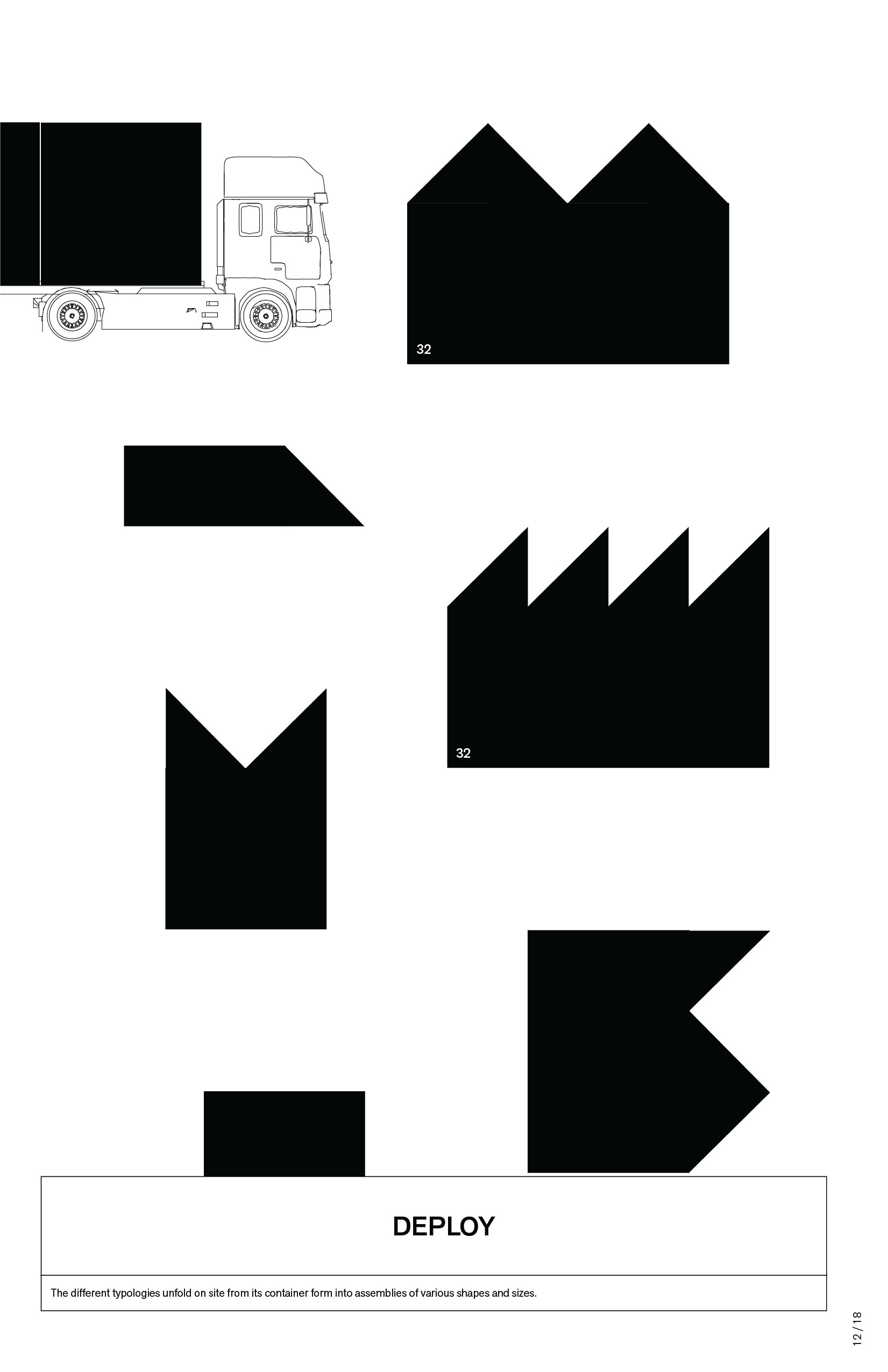

House Kits: Each truck load corresponds to the potential typologies and roof configurations that can be generated from a single kit

In OSM (Off-site Manufacturing) projects today, modularity is often addressed as means of production rather than design. Prefab houses are typically fabricated in a linear process where parts are manufactured and then put together either on-site or in a factory and will remain the same state until demolition.

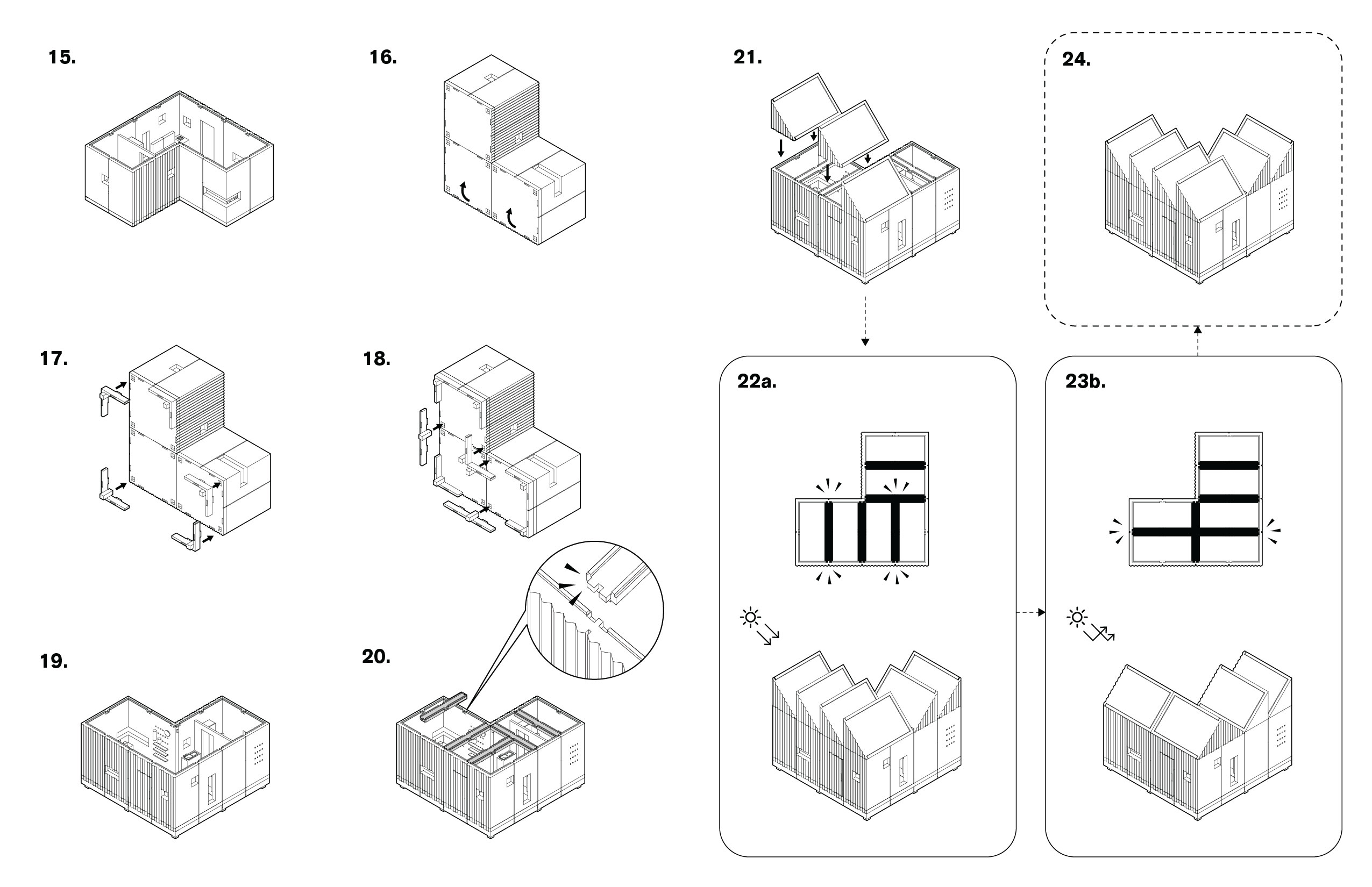

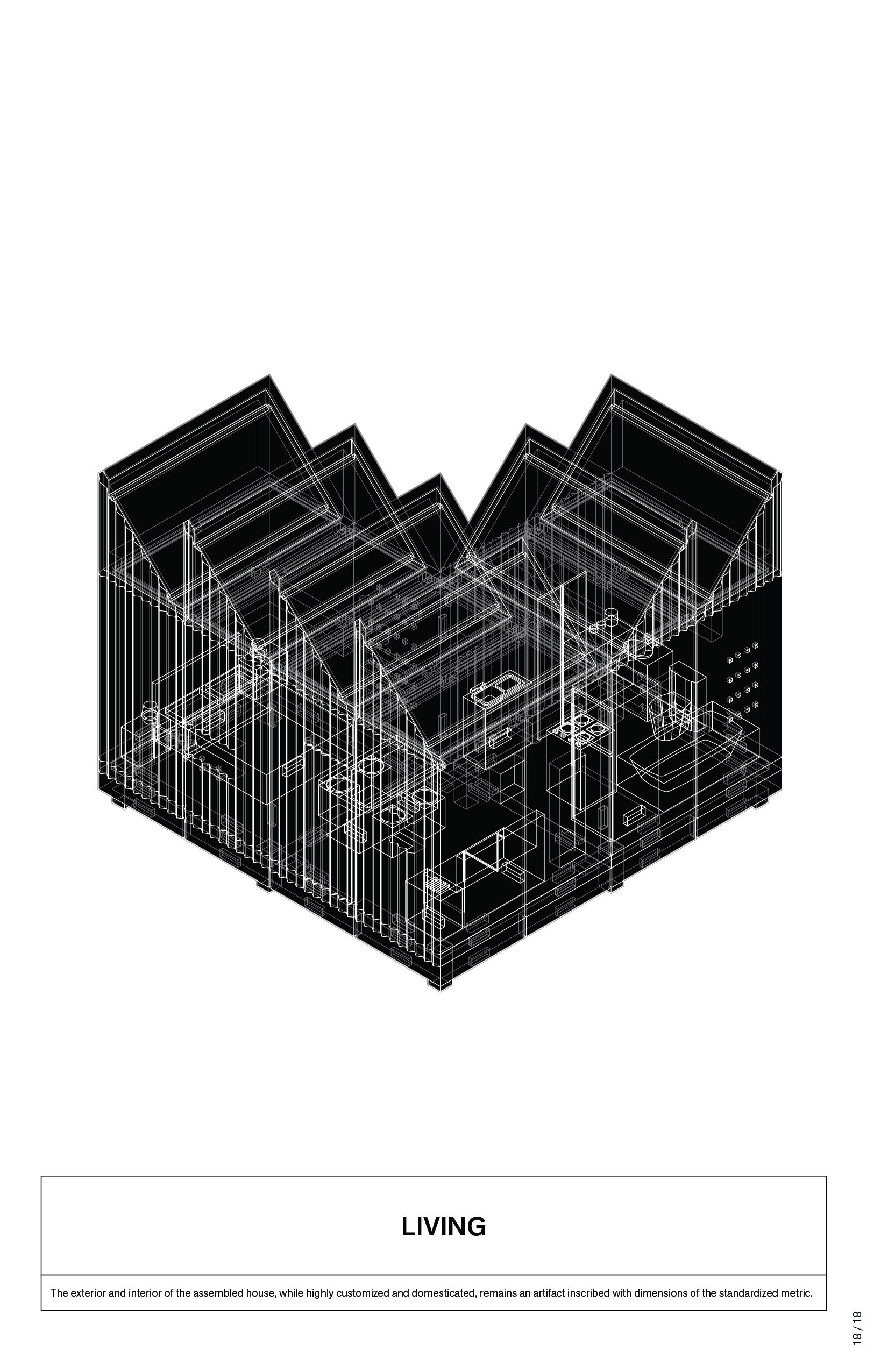

This project is interested in a non-linear process of OSM, where parts are manufactured and put together the same way, but possess the ability to be partially rearranged on site. The heavier interior volumes are fixed, where the lighter roofs are reconfigurable. The flexible roofscape allows for potential changes in program, seasons and occupants.

This project is interested in a non-linear process of OSM, where parts are manufactured and put together the same way, but possess the ability to be partially rearranged on site. The heavier interior volumes are fixed, where the lighter roofs are reconfigurable. The flexible roofscape allows for potential changes in program, seasons and occupants.

The current catalogue consists of 5 types of units: utility, service and 3 different sized interiors.

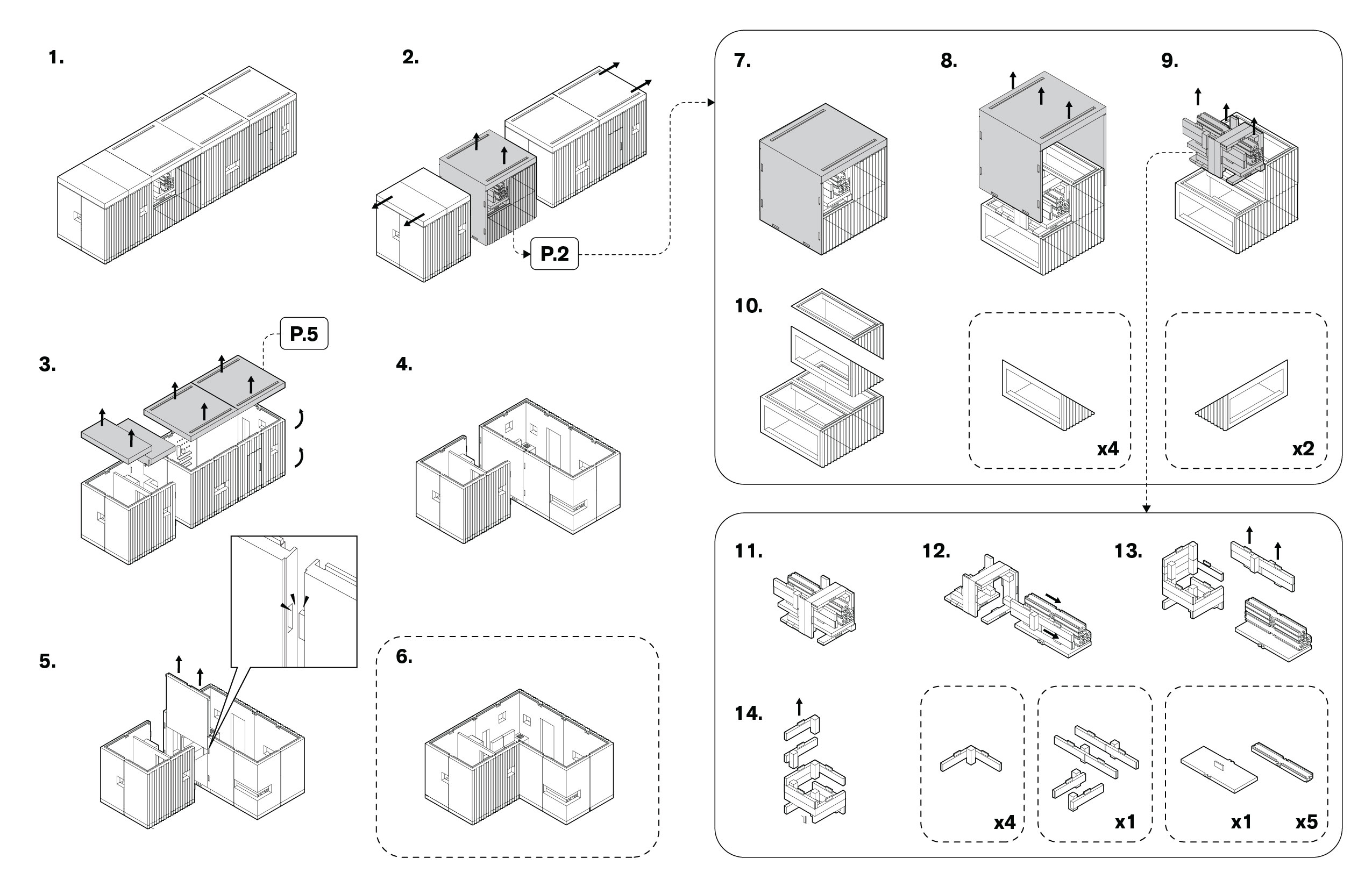

The dwelling units are fully customizable but their arrangements are fixed once shipped.

The service unit, which requires most planning because its access points are contingent to the sizes of the interior volumes it is connected to. I.e. for the 1-bedroom or studio kits, the service unit can only be accessed from a single side for the connection to remain enclosed. It is a different case for the 2-bedroom, in the configuration where the service unit is placed in the middle of a 9x9m house, where it can be accessed from all sides.

Lastly, the utility unit, which can house 8 semi-gables that are reconfigurable on top of interior units to form a full gable or sawtooth. This is easier to reconfigure than the heavier cranes it would have required to deploy the interior volumes and requires a smaller crane that is more accessible. The roofs can be rearranged between summer and winter for solar gain and a greater degree of direct/indirect sunlight depending on the program.

The dwelling units are fully customizable but their arrangements are fixed once shipped.

The service unit, which requires most planning because its access points are contingent to the sizes of the interior volumes it is connected to. I.e. for the 1-bedroom or studio kits, the service unit can only be accessed from a single side for the connection to remain enclosed. It is a different case for the 2-bedroom, in the configuration where the service unit is placed in the middle of a 9x9m house, where it can be accessed from all sides.

Lastly, the utility unit, which can house 8 semi-gables that are reconfigurable on top of interior units to form a full gable or sawtooth. This is easier to reconfigure than the heavier cranes it would have required to deploy the interior volumes and requires a smaller crane that is more accessible. The roofs can be rearranged between summer and winter for solar gain and a greater degree of direct/indirect sunlight depending on the program.

Unit off-loading, 1:20 scale

Beam configurations, 1:20 scale

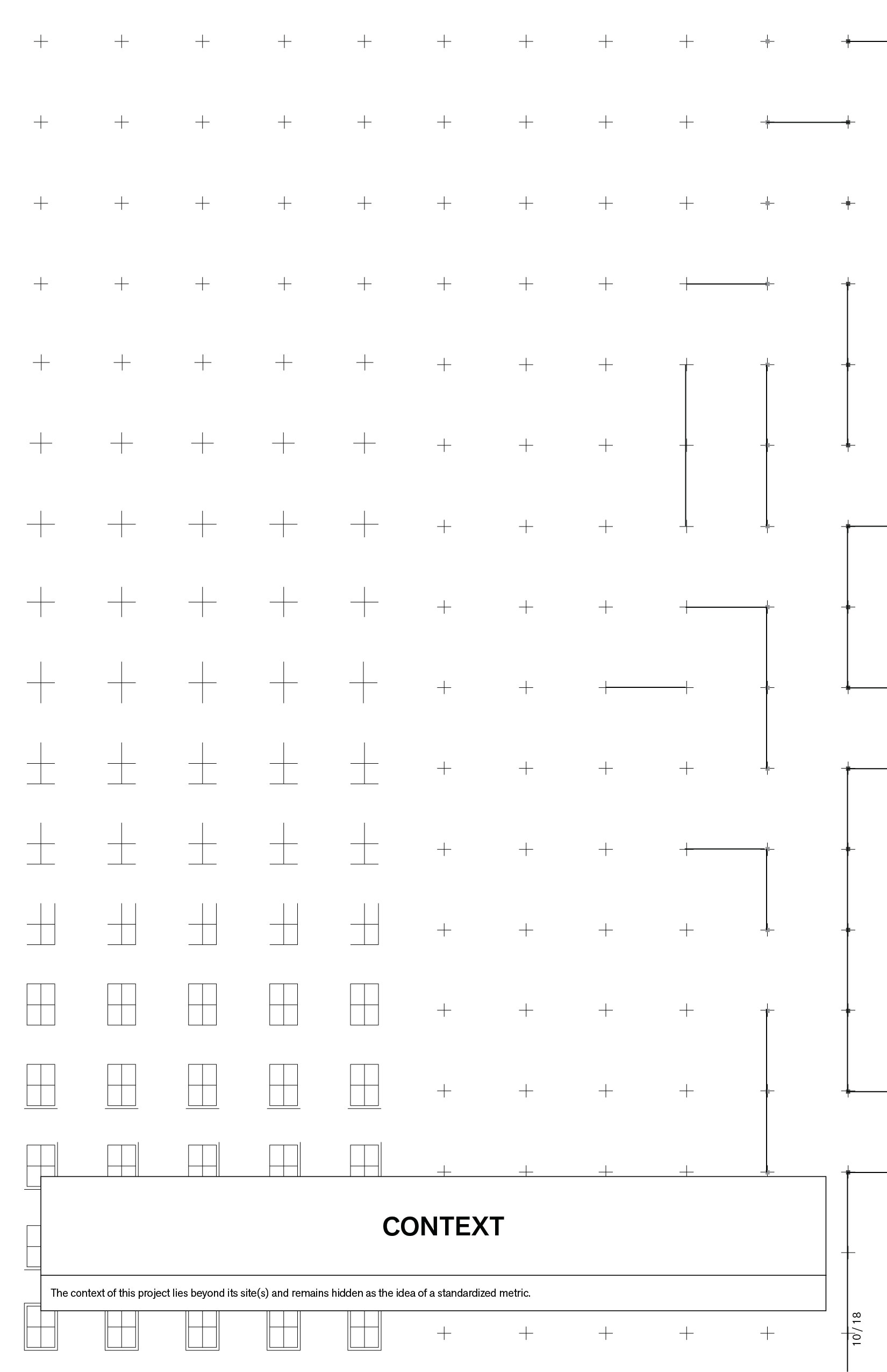

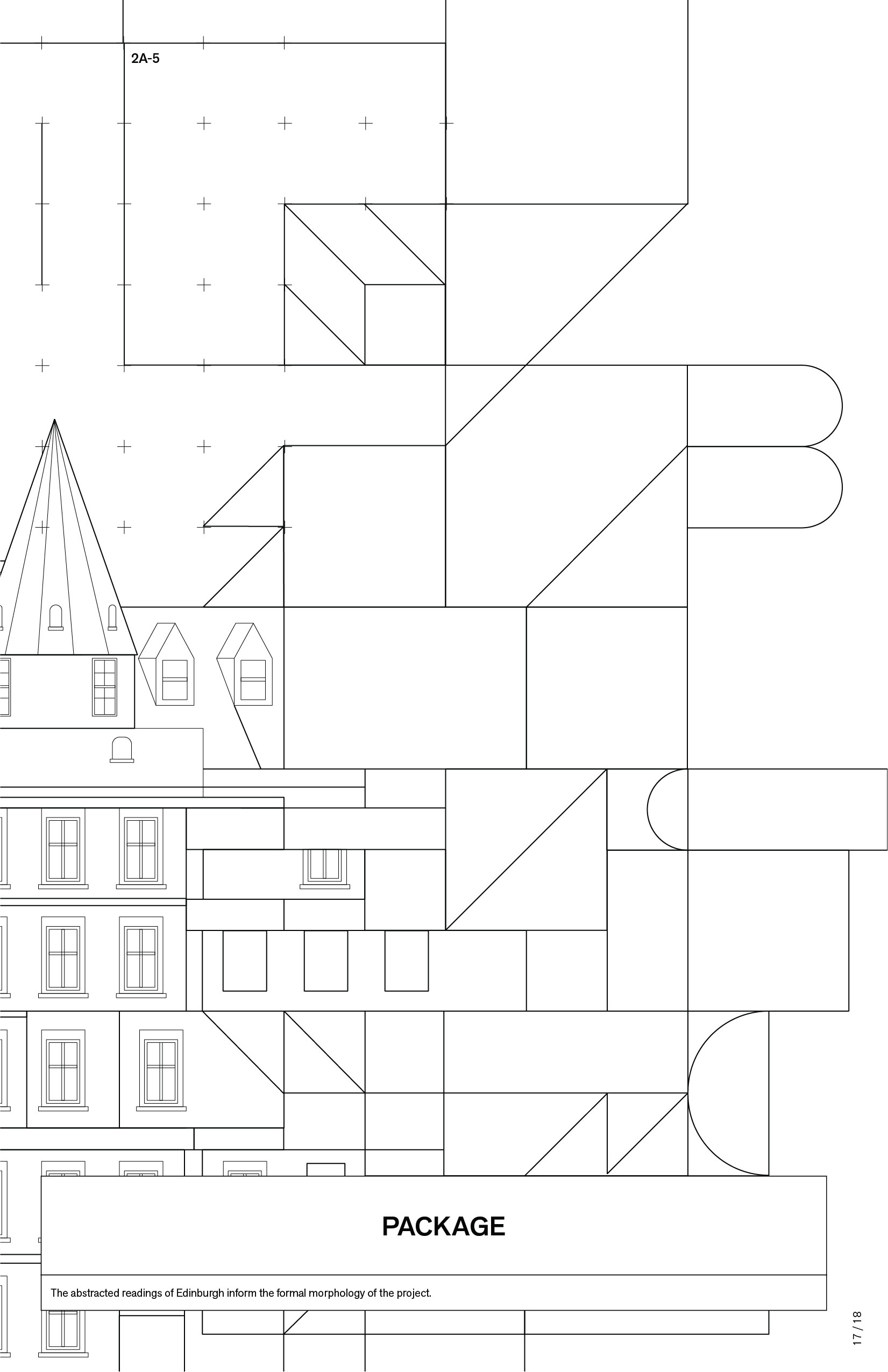

Metamorphosis diagram narrating a conceptual weaving between both the Waverly site and Falkland site through its “real” context of OSM.

This video outlines the entire construction process between the 1-bedroom kit house’s cargo configuration and living cinfiguration. For complete assembly details, please refer to the “1-Bedroom Kit House Assembly Manual”.